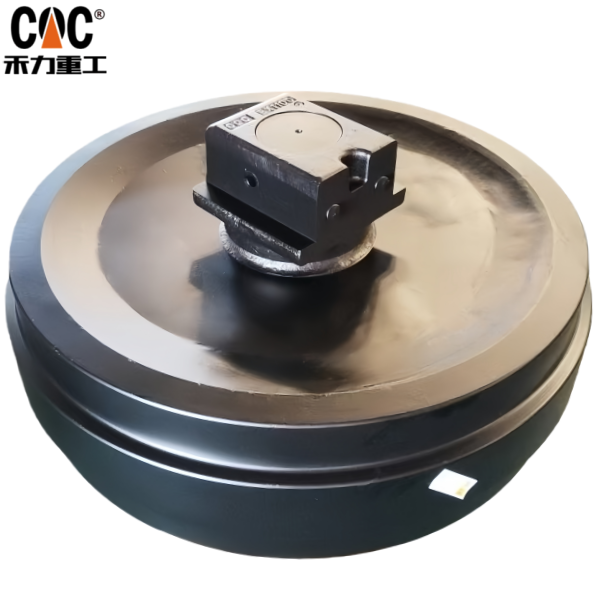

I-HITACHI 2044037 9101204 4390412 EX1100 Track Guide Wheel AS/Track Idler Assy-eyenziwe ngumkhiqizi kanye nomhlinzeki wezingxenye ze-chassis ye-HELI-CQC TRACK/Heavy-duty excavator

Ishidi Ledatha Lobuchwepheshe: I-HITACHI EX1100 Track Guide Wheel & Idler Assembly (P/N 2044037 / 9101204) – Yakhiwe yi-HELI-CQC TRACK

Incazelo ye-Meta: I-HITACHI EX1100 Track Guide yekhwalithi ye-OEM Wheel & Idler Assy (P/N 2044037/9101204).I-HELI-CQCikhiqiza izingxenye ze-chassis zomgubhi ezisindayo ezinobuchwepheshe obuthuthukisiwe bokubumba, ukwelashwa kokushisa, kanye nokuvala ukuze ziqine kakhulu.

1. Ukuhlonza Izingxenye kanye Nesifinyezo Sokusebenza

Izinombolo Zezingxenye ze-OEM: 2044037, 9101204

Isicelo: Abavubukuli Bezikebhe Ze-Hitachi EX1100 Series.

Amagama Ezingxenye:

- Isondo Lomhlahlandlela Womzila: Laziwa nangokuthi i-Bottom Roller noma i-Lower Roller.

- Ukuhlanganiswa Kwabavikeli Bomzila: Kwaziwa nangokuthi i-Front Idler.

Umkhiqizi Nomhlinzeki:ITHREKI YE-HELI-CQC, umkhiqizi okhethekile wezinhlelo zokuthutha ngaphansi kwenqola ezisindayo zomgodi.

Lezi zingxenye ezimbili ziyizici ezibalulekile zenqola engaphansi kwe-excavator, ezisebenza ngokubambisana ne-track chain, i-sprocket, kanye nama-carrier rollers ukuze kwakhiwe i-track circuit eqhubekayo.

- Isondo Lomhlahlandlela Wethrekhi (IDLER):

- Umsebenzi Oyinhloko: Usekela isisindo somshini futhi uqondisa ingxenye engezansi yochungechunge lwethrekhi.

- Ukusatshalaliswa Komthwalo: Ithwala umthwalo oyinhloko wesakhiwo, iwusabalalisa ngokulinganayo endleleni engezansi yethrekhi ukuqinisekisa ukuqina komhlabathi nokuvimbela ukucwila ngokweqile.

- Isiqondiso Somzila: Ama-flange ayo amabili agcina ukuhambisana kwe-track chain, evimbela ukuphuma kwesitimela ngesikhathi sokuhamba kanye nokuqondisa.

- Umhlangano Wokuvilapha Kwethrekhi (Ukuvilapha Kwangaphambili):

- Umsebenzi Oyinhloko: Uqondisa uchungechunge lwethrekhi ngaphambili kwesihlalo esingaphansi kwenqola futhi unikeza ukulungiswa kokucindezeleka.

- Incazelo ye-Track Contour: Iqondisa uchungechunge lwethrekhi phansi, idale "isimo se-D" se-track loop.

- Ukumuncwa Kokwethuka: Ngokuvamile kuhlanganisa i-spring noma i-hydraulic damper ukuze imunce imithwalo yomthelela evela ezithiyweni.

- Ukulungiswa Kokucindezeleka: I-idler ifakwe kumshini wokucindezela (isikulufu noma i-hydraulic), okuvumela ukulungiswa okunembile kokuqina kwe-track chain, okubalulekile ekusebenzeni kahle kanye nokuphila kwenkonzo.

2. Imininingwane Yobuchwepheshe Eningiliziwe Nomklamo Wobunjiniyela

I-HELI-CQCikhiqiza lezi zingxenye ukuze ihlangabezane nezidingo eziqinile zomshini wokumba we-EX1100 wekilasi lamathani ayi-100, isebenzisa ubunjiniyela obuthuthukisiwe kanye nesayensi yezinto ezibonakalayo.

A. Isayensi Yezinto Ezibonakalayo Nokubumba:

- Izinto Eziyinhloko: Isondo eliqondisayo kanye nesondo elingasebenzi kahle kuhlanganiswe ngokushisa ngama-alloy ensimbi anekhabhoni ephezulu, ane-manganese efana ne-50Mn noma i-60Si2Mn. Le nqubo yokwakha idala ukugeleza okusanhlamvu okuhle okuthuthukisa amandla okushaya kanye nokumelana nokukhathala okungaphezu kakhulu kwezinto ezilinganayo.

- Ama-Shafts nama-Bushings: Enziwe ngomshini wezinsimbi ze-alloy ezinamandla aphezulu (isb., 42CrMo, 40Cr) futhi ahlanganiswe nama-bushings ensimbi yethusi noma e-duplex amelana nokuguguleka ukuqinisekisa ukuthi ihlala isikhathi eside ngaphansi kwamandla okujikeleza aphezulu.

B. Ukwelashwa Kokushisa Okuthuthukisiwe:

- Ukucima Nokushisa (Q&T): Ingxenye yonke idlula kule nqubo ukuze kufezwe umongo oqinile, othambile (cishe u-30-40 HRC) okwazi ukumelana nemithwalo emikhulu yokushaqeka ngaphandle kokuqhekeka.

- Ukuqina Kokungeniswa: Izindawo ezigugile ezibucayi—indlela yokuxhumana egoqekayo kanye nama-flange aqondisayo esondweni lokuqondisa, kanye nomngcele we-idler—ziqiniswa ukungeniswa kuze kube ukujula okungu-5-8mm, kufinyelela ubulukhuni bomphezulu obungu-58-62 HRC. Lokhu kunikeza ukumelana okungavamile nokugugile okukhuhlayo ezimweni ezinzima zokumba kanye nokumba.

C. Uhlelo Lokuvala (Umklamo We-Labyrinth Weziteji Eziningi):

I-HELI-CQCisebenzisa uhlelo lokuvala olusezingeni eliphezulu olubalulekile empilweni yezingxenye ezindaweni ezingcolisiwe.

- Isivalo Esiyinhloko: Isivalo somlomo se-Nitrile Butadiene Rubber (NBR) esinzima, esithwala i-spring esigcina ukuxhumana njalo nendandatho yokuguguleka.

- I-Labyrinth Seal: I-Labyrinth Seal eyinkimbinkimbi, eneziteshi eziningi eyenzelwe ukudala indlela egobile ebamba futhi ikhiphe ngempumelelo izinhlayiya ezihuzukayo (udaka, isihlabathi, uthuli).

- Isithiyo Sokugcoba: Isikhala sokuvala sigcwele i-lithium-complex grease eshisa kakhulu, engangeni manzi, edala isithiyo sokucindezela esihle esivimbela ukungena kokungcola futhi siqinisekise ukugcotshwa okuqhubekayo kwezindawo zangaphakathi ze-bushing.

D. Ukugcoba Nokulungisa:

Zakhelwe njengezingxenye ezivaliwe futhi ezigcotshwe impilo yonke, azidingi ukugcotshwa kwangaphakathi okuvamile. Izithako zamafutha zangaphandle zinikezwa ukulungiswa kokucindezelwa kwethrekhi (idler) kanye nokuhlanza imigodi yesivalo sangaphandle.

3. Iphrothokholi Yokukhiqiza Nokuqinisekisa Ikhwalithi ye-HELI-CQC

I-HELI-CQCInqubo yokukhiqiza ihlelwe ngokubheka ukunemba nokulawulwa kwekhwalithi.

- Ukuhamba Komsebenzi Wokukhiqiza: Isitifiketi Sezinto Ezingavuthiwe → Ukwakha Ngokufa → Umshini Onzima → Ukucima Nokushisa → Ukuqinisa Ukufakwa → Umshini Wokuqeda I-CNC Oqondile → Umhlangano Wokuvala Nokufaka → Ukuhlolwa Kokusebenza → Ukupenda Nokupakisha Okulwa Nokugqwala.

- Ukulawulwa Kwekhwalithi Okuphelele:

- Ukuhlolwa Kobukhulu: Ukuqinisekiswa okungu-100% kusetshenziswa ama-precision gauges, ama-caliper, kanye ne-Coordinate Measuring Machines (CMM) ukuqinisekisa ukuhambisana nobukhulu be-OEM.

- Ukuqinisekiswa Kokuqina: Ukuhlolwa kweRockwell neBrinell kokubili enkabeni kanye nasezindaweni ezigugile zeqoqo ngalinye lokukhiqiza.

- Ukuhlolwa Okungonakalisi (NDT): Ukuhlolwa Kwezinhlayiya Ze-Magnetic (MPI) kusetshenziselwa ukuthola noma yiziphi iziphambeko noma imifantu engaphansi komhlaba ezingxenyeni ezibunjiwe ngaphambi komshini.

- Ukuhlolwa Kwe-Rotational Torque: Iyunithi ngayinye ehlanganisiwe ihlolwa ukujikeleza okubushelelezi, okukhululekile okunamanani e-torque acacisiwe, okuqinisekisa ukufakwa okufanele kokuvala kanye nokufakwa kwamabhere.

- Ukuhlolwa Kokuvuza Kwesivalo: Ukuhlolwa kokubola kwengcindezi kuqinisekisa ubuqotho bohlelo lonke lokuvala, okuqinisekisa ukuthi alungenwa ukungcola.

4. Ukuhlaziywa Kwemodi Yokwehluleka kanye Nezinzuzo Zokuqina

UkusebenzisaI-HELI-CQCizingxenye zinciphisa ukwehluleka okuvamile kwesisu esingaphansi kwesisu:

- Ukugqokwa Kwe-Flange Ngaphambi Kwesikhathi: Kulwiwa ngokuqina kwe-induction okujulile.

- Ukwehluleka Kwesivalo Nokungcoliswa Kwangaphakathi: Kuvinjelwa umklamo wesivalo se-labyrinth esinezigaba eziningi.

- Ukubanjwa Kwezingxenye: Kugwenywa ngokubekezelelana kwangaphakathi okunembile kanye nokuvala okusebenzayo.

- Ukuphuka Kwenhliziyo: Kuncishiswa ukwakheka okwenziwe ngobumba kanye nokuqina okufanele kwenhliziyo okuvela ekwelashweni kokushisa kwe-Q&T.

5. I-HELI-CQC TRACK: Umlingani Wokukhiqiza Onobuhlakani

I-HELI-CQCimelela isiqongo sokukhiqiza izinqola zangaphansi ezithwala umthwalo osindayo, okunikeza:

- Ukushintshwa Okuqondile kwe-OEM: Izingxenye zenzelwe ukushintshaniswa okuphelele nezingxenye zokuqala ze-Hitachi.

- Ukukhiqiza Okuhlanganisiwe Okuqondile: Ukulawula okugcwele inqubo yokukhiqiza kusukela ekubumbeni kuya ekuhlanganisweni kuqinisekisa ikhwalithi eqhubekayo kanye nokusebenza kahle kwezindleko.

- Ukusebenza Kwensimu Okuqinisekisiwe: Izingxenye zaklanywa futhi zahlolwa ukuze zinikeze impilo yesevisi efana, noma edlula, izingxenye ze-OEM ezimweni zokusebenza ezifanayo.

- Amandla Omhlaba Wonke Okunikezela Ngempahla: Amandla okusebenzela izimakethe zomhlaba wonke ngempahla ethembekile, okuqinisekisa ukuthi isikhathi sokungasebenzi sincishisiwe kubasebenzi bemishini emhlabeni wonke.